Generative Design in UX Discipline

From the era of the manufacturing process led by humans to the one based on automatic machines, there has been a great change in the manufacturing landscape. The use of technology has offered a smooth path that is not only efficient but also friendly.

Generative Design is one such advancement that can even add more value to the manufacturing landscape. The exploration process is one of the high-performing design alternatives; this method can help choose the best fit from multiple options.

A system that helps the engineers create optimal designs from a set of system design requirements and interact with the technology to positively drive the product, generative design architecture is one of the finest tools to use.

Source: cimdata

What is Generative Design? - A Brief Introduction.

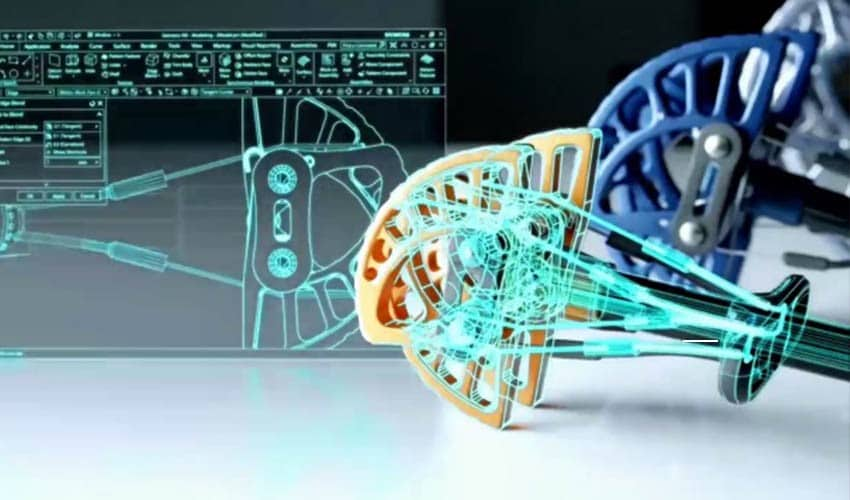

Technology is changing the manner of producing the products. With the immense development and adaptations, the use of technologies like additive manufacturing, artificial intelligence algorithms, unlimited cloud computing power, and generative design tools has helped engineers design effectively compared to the traditional development lifecycle in less time.

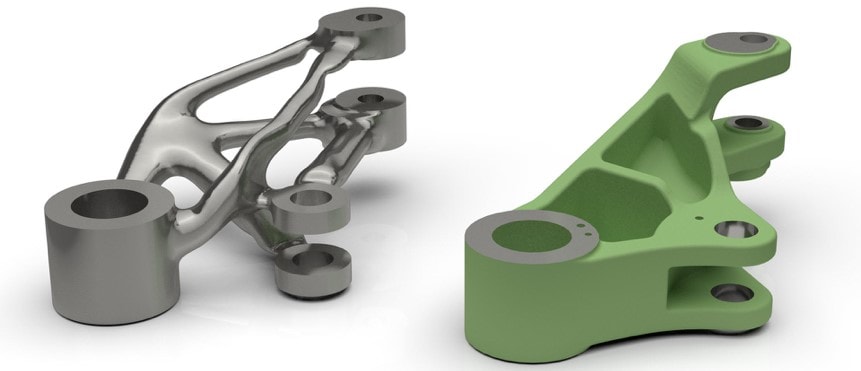

The generative design definition involves the complete iterative design process involving software that will generate a certain number of outputs meeting specified constraints to reach the best solution. This is a method that involves the use of computer technology, real-world constraints and offers intended output.

The broad category of information that the user needs to input in the system while using the generative design online are:

- Information about the physical constraints

- Information regarding the forces, pressures, and loads

- Information about the materials that might be considered for the creation

- Information about the manufacturing process

The generative design relies on the use of artificial intelligence and machine learning, which is an evolutionary approach. The advantages that the use of generative design architecture are as follows:

Unlimited choices

The use of the generative design is based on the information imputed by the user. Based on the principle of permutation and combination, the process produces several iterations despite the specified constraints. With the plethora of options, the engineer can choose the option that is more effective and efficient.

Ease in overcoming barriers to creativity

The manner in which the generative design operates is way beyond the working of the simple technological design. Working professionally also helps overcome the creativity barrier and offer solutions that eliminate the weak design areas and improve the overall performance.

Automated adjustments

The generative design architecture is one step ahead that is capable of performing automated adjustments. The iterative process uses information and constraints to offer a design that one can change quickly and easily. By adding the new conditions, one can automatically design a new and more effective design.

Reduced lead time

There are numerous instances where there is a need for making a last-minute change that can cause hassle and confusion. The use of generative design architecture offers the advantage of creating multiple design options within a short period that reduces the overall lead time.

Reduced cost

Using the generative design architecture eliminates the requirement of additional simulation or testing. While the complete design is based on the safety norms, constraints, and inputs, the cost is reduced. This helps in freeing up the budget and utilizing the funds in more effective and efficient ways.

Free uptime

One of the unique advantages of generative design is that it helps the designer skip the need to manually navigate the design options or check each of them separately. This frees up the time that one can utilize in more practical engagement or strategic areas.

The generative design helps reduce the overall manufacturing load, saving time and reducing the workload, which will increase productivity.

An Example of Everyday Generative Design.

From manufacturing to aerospace, architecture, and construction, there is a wide range of examples where generative design architecture is utilized. Additionally, generative design fusion 360 is one of the high-end technological upgrades with optimized geometry and solves complex engineering problems.

Generative design is one of the key aspects that will help design the fuel-efficient car design. One of the finest examples of generative design is in the field of aircraft manufacturing. The technique helped design the most famous aircraft, Airbus A320, that bought the complex design and optimized the geometries that would not have been possible using traditional manufacturing and designing processes.

Generative design is one of the key tools that help companies make breakthrough design achievements and overcome engineering challenges. With the policy of less waste and more productivity, the use of generative design architecture has been an immersive experience for the companies.

Common Uses for Generative Design.

The use of Generative Design is far and wide and offers a range of services that offers optimization and leads to better use of resources. Effective designing helps the companies to build a better and efficient base of customers. The technology is not only used in the lab but is one that is applicable in various fields like:

- In the automotive industry, to design lightweight components, fuel-friendly vehicles, and compact designs.

- The aerospace industry uses the same for the design and manufacturing goals linked to the aspects of weight reduction, environmental impact, and safety.

- In architecture and construction, technology is used in designing buildings that are more suitable and meet the design goals.

- In the manufacturing industry, the technology is used in designing the parts and tools with more effective design, low waste generation, better lead time, and enhanced benefits to the users.

- Industrial machinery is one key field where generative design is applied. It helps by designing tools and equipment that are innovative and more effective.

- In simplifying the complex building products and making them more sturdy, generative design and additive manufacturing are applied.

- The consumer-based industry is always seeking innovative and user-friendly goods. The use of generative design offers an opportunity to have a positive impact on innovation and productivity.

The relationships between Generative Design and UX.

Generative design architecture has helped industries and businesses reduce waste and optimize their overall process. By offering the design of more effective and user-friendly products, the technology has helped to gain a more satisfied base of customers.

The key aspect of the relationship between the generative design and the UX is to offer a customer experience that far surpasses the customers' expectations. The points that are considered to attain the positive relationship between the generative design and UX are:

- Offering the products that are effective and efficient

- Innovative services that offer a greater degree of accessibility and usability

- Improving performance by reducing the chances of errors and wastage.

- Improving the innovative aspect by overcoming the creative barrier

- Focusing on real-world constraints helps to use the product more effectively.

Conclusion

Although the advantages that the generative design architecture offers to businesses and users are immense, there are still a few disadvantages that one needs to focus on. On the one hand, it improves productivity and innovation, making manual innovation and human efforts redundant.

Generative design in the crucial manufacturing fields has proved to be one of the most effective tools that can eliminate waste, reduce cost, and help companies focus on innovation. The efficiency with which the generative design fusion 360 operates and generates results has made it the future of manufacturing, a tool that offers innovation and creativity.